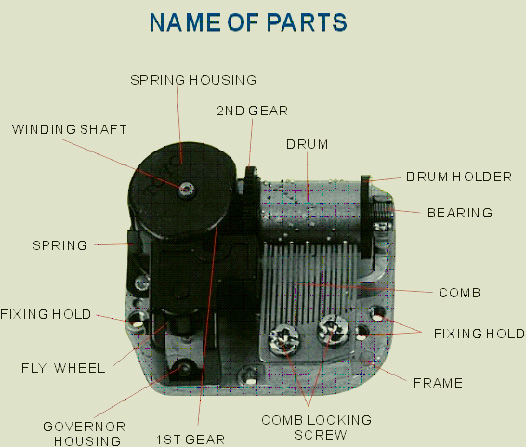

THIRD GENERATION OF TOYO MUSICAL MOVEMENTS

1-1 DESCRIPTION DETAILS

Model Name 26ST-S

*26 = Spring; *ST = Size; *S = Engineering Variation

S = Standard

Spring Type 224 Least Torque

26 Standard Torque

28 Stronger Torque

30 Strongest Torque

1-2 IMPROVEMENT OF SIZE

Its smaller and lighter, we have reduced the module size and modify the material, in order to reduce the over all size and weight.

For example : 3rd generation - 26ST-S = 65g

1st generation - 18N-S = 82g

1-3 CONSISTENCY OF PLAYING SPEED

Modified engineering of speed governor has allowed us to achieved a

consistent music playing speed.

1-4 IMPROVEMENT OF SOUND QUALITY

Modifying of the tune plate material, gears and speed governor in all has assisted in the reduction of mechanical noise.

1-5 REDUCTION OF DEFECTIVENESS

Reinforcement support of the speed governor protects the musical

movement from impact. Thus, eliminating the defective rate.

PROPER FORMATS TO HANDLE MUSICAL MOVEMENTS

2-1 SPEED GOVERNOR

1. When using a stopper function. Assembling the piston or wire stopper

mechanism is depressed, it causes the other end of the wire (next to the flywheel) to rise and stop the flywheel. Thereby, stopping the musical

mechanism from functioning.

2. Avoid stopper to collide directly with the pinpion which would cause the pinpion to be deformed.

3. Keep minimum contact between stopper and flywheel.

4. Do not hold and press the governor assembly with excessive force.

2-2 DRUM SHAFT EXTENSION

1. Clockwise Force

Extra force should be applied clockwise to drum's extension shaft.

(Maximum 15kg/mm)

Precaution: Once withdrawal is released from the drum's extension

shaft. It would not be able to reapplied again.

2. Perpendicular Force

Excessive force will damage the plastic gear. When pulling or pushing

perpendicular to gear maximum force should not exceed 17.5 kg/mm.

2-3 FIRST GEAR SHAFT

Maximum 30 kg is allowed to apply on gear shaft to avoid damaging of the plastic gear.

2-4 MAXIMUM ALLOWANCE FORCE FOR

28ST-CR198 500g-520g

28ST-PH102 Clockwise 700g-720g

28ST-PH102 Perpendicular 450g-470g

28ST-F2 950g-970g

PROPER HANDLING OF MUSICAL MOVEMENTS

Musical movements are very precise mechanism. Please be cautions of mishandling of musical movement.

1. During Transportation and Storage.

A. Avoid strong impact and collision.

B. Do not over stack boxes, maximum of 12 boxes laid on top of each

other is recommended.

2. Store musical movements at room temperature and a dry location.

3. During assembly and packaging in the factory avoid damaging the

flywheel assembly.

Copyright 2005 owned by Sanfield Precision Limited.

All right reserved.

著作權所有誠輝精密有限公司

All right reserved.

著作權所有誠輝精密有限公司